Introduction

In industrial power transmission, Hydraulic Cylinders are known as the "muscles of industry." Whether it's the steel giants on construction sites or the precision automated production lines in factories, hydraulic cylinders play a core role in converting hydraulic energy into linear reciprocating mechanical energy.

However, when designing hydraulic systems or selecting equipment for maintenance, engineers and purchasing personnel often face a fundamental yet crucial choice: should they choose a simpler single-acting cylinder or a double-acting cylinder?

This article will thoroughly examine the differences between the two from multiple dimensions, including physical principles, internal structure, control logic, and economic benefits.

Single-Acting Cylinders

What is a single-acting cylinder?

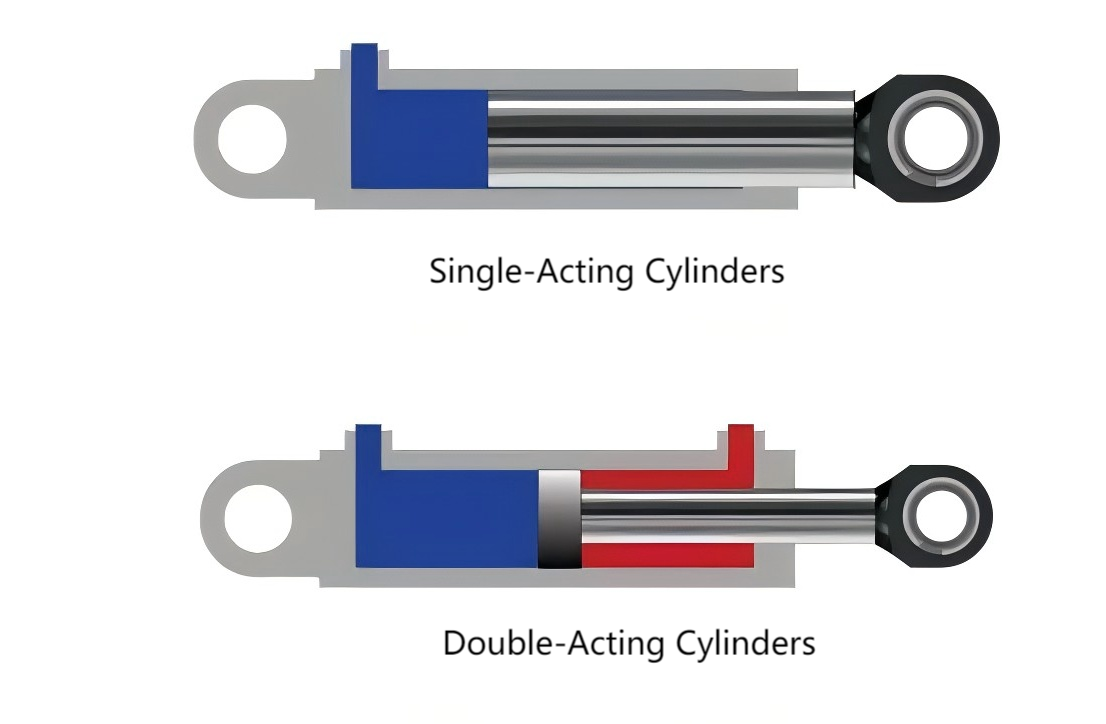

The definition of a single-acting cylinder is very straightforward: hydraulic oil acts on only one side of the piston, producing thrust in one direction (usually extension).

Working Principle and Return Method

In a single-acting system, when high-pressure oil enters the cylinder's inlet port, the piston extends under pressure. However, when the piston needs to "return," the hydraulic system does not provide reverse power, but relies on external forces:

Gravity return: The piston is pushed back by the weight of the load itself (e.g., the cargo box of a dump truck).

Spring return: A large spring is installed internally, and the spring automatically returns to its original position after the pressure disappears.

Mechanical return: An externally connected mechanical device forcibly pulls it back.

Advantages of Single-Acting Cylinders

Lower system cost: Requires only a single oil line and a simple control valve.

Compact structure: Due to the lack of complex internal bidirectional sealing requirements, it is easier to install in certain confined spaces.

Lower energy consumption: The return stroke does not consume hydraulic pump power, making it very energy-efficient in specific gravity-assisted applications.

Limitations

The limitation of a single-acting cylinder lies in its "passivity." It cannot output power during the return stroke, and the return speed is limited by the external load or spring strength, making it difficult to achieve precise cycle timing control.

What is a double-acting cylinder?

Double-acting hydraulic cylinders have two ports. Hydraulic fluid can enter both sides of the piston alternately, generating thrust or pull in both extension and retraction directions.

Differential Motion and Control

Due to the presence of the piston rod, the effective force-bearing area on both ends of the piston is unequal (rod side vs. rodless side). This results in the extension force of a double-acting cylinder usually being greater than the retraction force at the same pressure, but the retraction speed is faster. Through precise proportional valve control, double-acting cylinders can achieve extremely smooth, high-speed, and accurate position control.

Advantages of Double-Acting Cylinders

Bidirectional operation: Can both push and pull, offering wide adaptability.

High control accuracy: Speed and force are under the control of the pump station regardless of the direction of movement.

High cycle efficiency: Capable of reciprocating motion at very high frequencies, suitable for highly automated production lines.

Limitations

More complex structure, meaning more seals (increased risk of leakage), more piping (dual oil circuits), and higher system acquisition costs.

Comparison

To understand more intuitively, we can compare them across the following five key dimensions:

Valves and Piping

Single-acting: Usually uses a three-way three-position valve or a simpler single-channel switching valve.

Double-acting: Must be equipped with a four-way valve (such as a three-position four-way solenoid Directional Control Valve), resulting in more complex system wiring.

Seal Design

Single-acting: Only needs to consider unidirectional pressure sealing.

Double-acting: The piston must be equipped with a bidirectional sealing ring to prevent high-pressure oil from "leaking" between the two chambers.

Maintenance and Durability

Single-acting cylinders have fewer parts and therefore fewer failure points; however, if it is a spring return type, spring fatigue failure is a potential risk. The main maintenance focus for double-acting cylinders is the wear of the piston seals.

Application Scenarios (Typical Cases)

Single-acting: Scissor lift platforms, construction jacks, dock loading bridges.

Double-acting: Excavators (boom, bucket), CNC machine tools, die-casting machines, industrial robot joints.

Summary

In actual procurement or design, do not blindly pursue "all-inclusive functionality." The following decision tree can be used as a reference:

Does the load always move in a fixed direction?

Yes (and no force is needed for the return stroke): Prioritize single-acting cylinders.

No (requires both pushing and pulling): Double-acting cylinders are necessary.

Are there requirements for the return speed?

It doesn't matter, as long as it returns: Single-acting cylinders.

Requires fast and precise return: Double-acting cylinders.

What are the space and budget constraints?

Extremely budget-sensitive and limited space: Single-acting cylinders.

Seeking long-term system stability and functional expandability: Double-acting cylinders.

Media Contact

Company Name: Qingdao Micro Precision Machinery Co., Ltd.

Email: Send Email

Phone: +86-15589891818

Address:No. 438, Wangsha Road, Chengyang District

City: Qingdao

Country: China

Website: https://www.mpmmachine.com/